Recycling concrete reduces environmental impactsSponsored

THE DEMAND FOR RECYCLED AGGREGATE IS ON THE RISE. ONE OF THE MOST COMMON EXAMPLES OF SUCH PRODUCTS IS RECYCLED CONCRETE

MSC offers the Cobra range of ‘Impact Crushers’ that are designed to efficiently and effectively reduce materials, including concrete and many types of minerals.

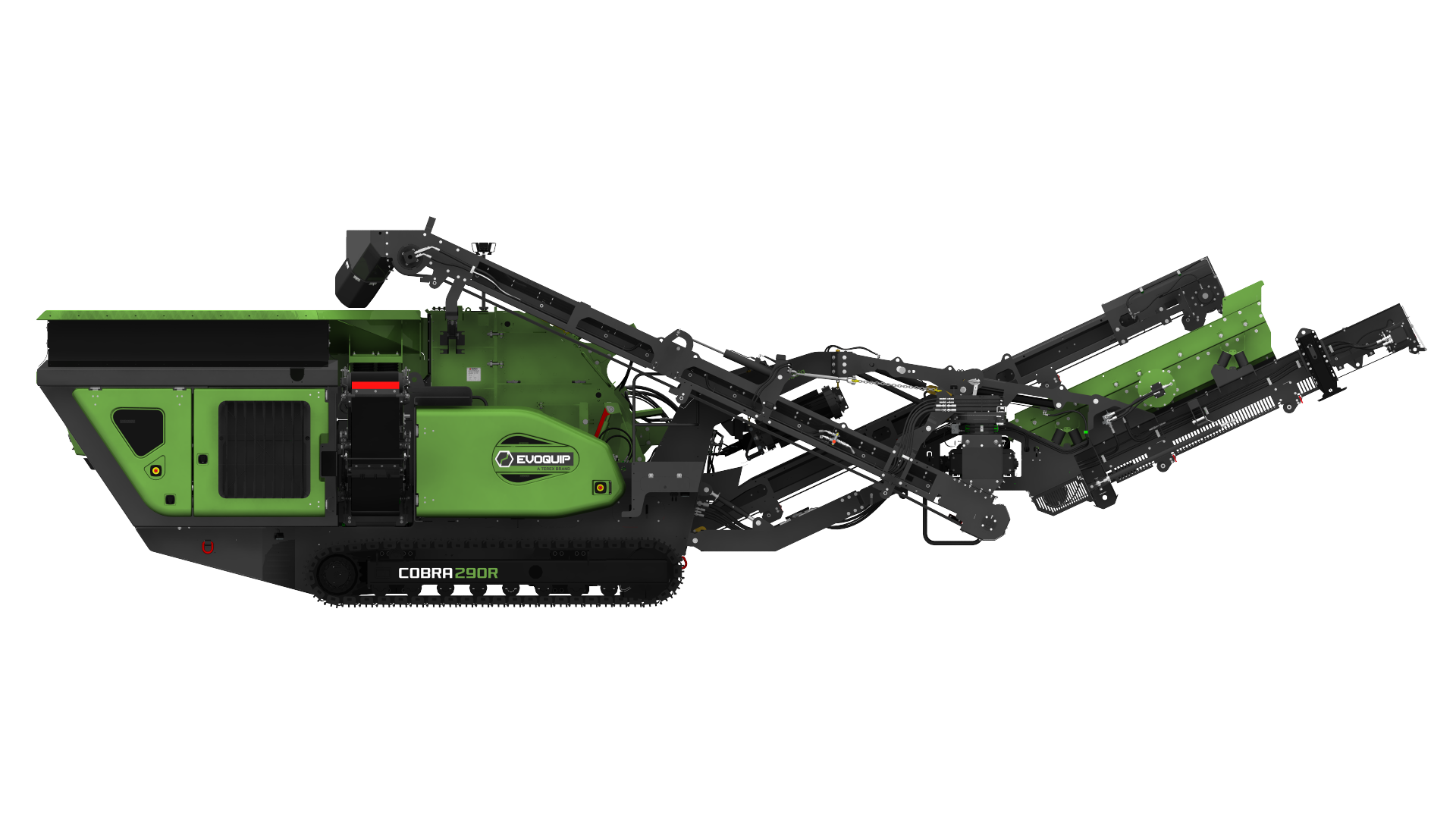

EvoQuip Crushing – Cobra 230R & 290R

The compact Cobra 230R can operate in even the most demanding of applications such as reinforced concrete. The integrated afterscreen system on the Cobra ensures the required product specification is achieved with oversize material either being recirculated back to the crusher or else stockpiled.

These primary impact crushers are productive for recycling, in addition to many aggregate-crushing operations. Impact crushers shatter materials by striking them with blow bars mounted on a horizontal rotor. Rotor speed can be varied according to the type of application and materials being crushed.

EvoQuip Cobra impactor crushers are easily transported wherever needed and feature a quick site setup time. They are compact, self-contained crushers designed for use in cramped urban areas with space restrictions.

Cobra impact crushers can be set up at road, demolition, or construction sites to crush on the spot for potential immediate use of product.

SUCCESSFUL RECYCLING – OVERLOAD PROTECTION

Cobra crushers have an overload protection feature. This functionality enables continuous crushing and protects the crusher from extreme overloads.

PRODUCT FOCUS: COBRA 290R Impact Crusher (Stock arriving soon in NZ)

COBRA 290R – Key features

- Perfect solution for on-site recycling in urban areas

- Fuel-efficient and high-performing direct drive system

- Easily transported from job to job

- Ready to crush in minutes as a result of ground level set-up

- Intuitive two-button start-up sequence

- Versatile and easy to use and can operate in the most demanding of applications

- Two independent hydraulic controlled aprons which allow the operator to optimize the material throughput and reduction.

- The patented hydraulic overload protection system protects the crusher in the event of an uncrushable piece entering the chamber and minimizes apron bounce.

- Oversize material either being recirculated back to the crusher or stockpiled.

COBRA 290R – Technical specifications

- Hopper: Hopper capacity – 3.3m3

- Output: Up to 290 tph

- Crusher: Crusher inlet – 1030mm x 790mm

- Pre-screen: 2.74m x 1.5m post screen

Integrated pre-screen which can be configured to suit multiple applications - Afterscreen: Aggressive 9’ x 5’ single deck screen

- Conveyor: Conveyor – 1m (W)

- Feeder: Vibrating feeder

‘Concrete Recycling’ – Terex EvoQuip Bison 280 Jaw Crusher, on machine hire in Auckland.

RECYCLING IS THE SMART, COST-EFFICIENT, AND ENVIRONMENTALLY FRIENDLY WAY TO REUSE DEMOLITION CONCRETE

Interested in exploring concrete recycling as a sustainable solution?

- Production waste is an issue, and concrete is a major contributor. Concrete recycling reuses concrete already produced and ultimately reduces landfill waste

- Producing recycled concrete aggregate minimises the impact on the environment, compared to producing natural aggregates

- Recycled concrete is a viable alternative to quarry products

Environmental impacts

- Simply by reusing and recycling concrete waste, you can make a positive impact on the environment!

- Reusing concrete waste provides customers with affordable, sustainable concrete alternatives

- Recycled concrete aggregates make a great alternative to quarry aggregates

- By reusing concrete, you can be part of the shift towards a more sustainable way of demolition, construction, and landscaping!

- Using recycled concrete saves both the environment and money

- Recycling consumes less raw material and preserves gravel resources

- Fewer transportation needs, which means lower fuel consumption. Using EvoQuip mobile crushers, crushing can be done on-site and material can immediately be used there again as filling material. This also means less material goes to waste and ultimately, less dumping ground space is needed

- Recycling turns unwanted concrete into sought-after quality end products

Recycled concrete is a valuable resource. Recycled concrete can be used in a range of landscaping and construction applications, including:

- Driveways

- Drainage

- Decoration

- Pathways

- Retaining wall fillings

- Sub-bases

- Under slabs

Machine – EvoQuip Colt 800. Product type – Processed recycled concrete application.

Union Demolition – Auckland

Contact MSC to discuss how Terex Screens, Crushers & Stacker solutions can benefit your operations.

Although Auckland based, MSC operates NZ-wide in both Sales and Hire.

SALES:

0274 939 098 | andy@mobilescreening.co.nz

0272 255 838 | dan@mobilescreening.co.nz

HIRE:

0272 255 525 | matt@mobilescreening.co.nz

P 0800 MSC LTD